Medication device

Shandong Zhilin Environmental Protection Technology Co., Ltd. manufactures and sells a wide range of high-efficiency intelligent heat exchangers, plate heat exchangers, high-efficiency plate heat exchangers, high-temperature plate heat exchangers, detachable heat exchangers, water-to-water plate heat exchangers, gasket plate heat exchangers, detachable plate heat exchangers, and steam-water high-efficiency plate heat exchangers. These products are widely used in metallurgy, mining, petroleum, chemical, power, pharmaceutical, food, chemical fiber, papermaking, light textile, shipbuilding, and heating industries. They can be used for heating, cooling, evaporation, condensation, sterilization, disinfection, and waste heat recovery. The company has senior engineers and technicians who can assist with engineering design, product solutions, equipment selection, product drawing design, commissioning services, and technical consultation. It also boasts a modern production workshop, advanced production processes and testing equipment, and a complete quality assurance system and testing methods.

Classification:

Medication device

Details

Shandong Zhilin Environmental Protection Technology Co., Ltd. manufactures and sells high-efficiency intelligent heat exchangers, plate heat exchangers, high-efficiency plate heat exchangers, high-temperature plate heat exchangers, plate heat exchangers, detachable heat exchangers, water-water plate heat exchangers, high-efficiency plate heat exchangers, gasket plate heat exchangers, detachable plate heat exchangers, steam-water high-efficiency plate heat exchangers, etc. These products are widely used in metallurgy, mining, petroleum, chemical industry, power, medicine, food, chemical fiber, papermaking, light textile, shipbuilding, heating and other sectors. They can be used for heating, cooling, evaporation, condensation, sterilization, and waste heat recovery. The company has senior engineering and technical personnel in the industry and can assist in engineering design product solutions, equipment selection, product drawing design, operation and debugging services, and technical consultation. It has a modern production workshop, production processes and testing equipment, a complete quality assurance system, and testing methods.

Product Introduction

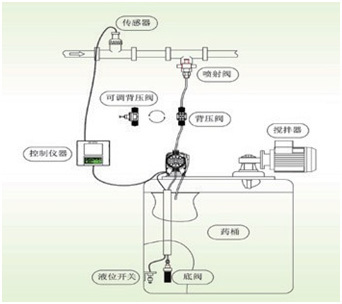

1. The chemical dosing system uses a metering pump as the main dosing equipment. It assembles the dissolving tank, stirrer, dosing device, liquid level gauge, safety valve, check valve, pressure gauge, filter, buffer, pipeline, valve, base, ladder, automatic monitoring system, and electrical control system according to the process flow requirements to form a complete set of chemical dosing system. It can realize local control, remote automatic control, and manual and automatic switching dosing. It features compact structure, small size, low noise, stable operation, simple installation, and convenient operation.

2. The chemical dosing system accurately configures various solid and liquid chemical solutions through different process designs and then uses a metering pump for accurate dosing to meet various design requirements, such as descaling, deoxygenation, coagulation, acid addition, and alkali addition. The dosing process can be manually operated or automatically controlled through a PC, magnetic level gauge, PH meter, stroke controller, frequency converter, and other electrical appliances and instruments, making the dosing system a mechatronics product.

3. The dosing amount and dosing pressure of the chemical dosing system can be selected according to the needs of the industrial process. The flow rate ranges from 1L/h to 8000L/h, and the pressure ranges from 0.1MPa to 25MPa. The metering accuracy of the metering pump can be as high as ±1%, and it can achieve simultaneous transportation and individual adjustment of multiple media. The volume of the solution tank in the dosing system can range from a minimum of 0.1m3 to 20m3, which can be selected according to the dosing amount. Various materials are available depending on the medium being transported, such as carbon steel (carbon steel lined with rubber), stainless steel, and non-metallic materials (PE, PVC, PP, PTFE), etc.

Typical Installation Diagram