Vacuum deaeration device

Classification:

Vacuum deaeration device

Details

Product Introduction

The XMC series rotary film deaerator is a thermal deaerator that removes dissolved oxygen and other gases from the feed water of thermal systems, preventing corrosion of thermal equipment. It is widely used in various power plant boilers and industrial boiler feed water deoxygenation sites.

The rotary film deaerator is developed based on the original film-type deaerator. It is a new scientific research achievement announced by the State Science and Technology Commission and has won the third prize of scientific and technological progress of the Ministry of Energy. The Northeast Electric Power Administration Technology Development Company undertook the research and development project and designated our company as the production base. After years of efforts, it has been serialized, with output ranging from 4 to 1080t/h. The newly designed and produced rotary film deaerator has higher technological content and more stable performance.

Structural Features

(1) Structure

The rotary film deaerator consists of two main parts: a deaerator tower and a water tank. Feed water deoxygenation and heating are mainly completed in the deaerator tower. The water tank is used for water storage, buffering, and deep deoxygenation, and also has an auxiliary function of preheating when the boiler is supplying water and ensuring the safe operation of the feed water pump. Two deoxygenation components are installed in the deaerator tower. The membrane tube of the primary deoxygenation component is the main part for heat and mass transfer, and the quantity and process structure arrangement need to be selected according to the design parameters. The secondary deoxygenation component is a wire mesh corrugated packing. Steam pipes, water distribution pipes, reboiler pipes, anti-rotation devices, and connecting pipes are installed in the deoxygenation water tank. Measuring and display instruments are also installed on the deaerator tower and water tank.

(2) Features

High deoxygenation effect: The oxygen content of the deoxygenated water is ≤ 30μg/L during unit startup and ≤ 7μg/L during operation, fully meeting the requirements of the "Water and Steam Quality Standard for Thermal Power Plants" and reaching the currently internationally used values.

Strong adaptability: Applicable to operation under conditions of high inlet water dissolved oxygen (low-pressure type: 10000μg/L, high-pressure type: 2000μg/L); low inlet water temperature (low-pressure type: 13℃; high-pressure type: 60℃); and large pressure changes (low-pressure type: -0.002~0.49MPa; high-pressure type: -0.05~1.60MPa). The operation mode can be used for sliding pressure, constant pressure, or negative pressure operation.

Good stability: When the load changes suddenly by 25%, the feed water is instantaneously supplemented by 10%, when a low-temperature steam source is used; when the inlet water temperature is significantly reduced, the deoxygenated water can still meet the standard, and the deaerator will not experience vibration or other abnormal situations.

Energy saving: Small exhaust steam volume, no need for additional exhaust steam cooler, simplifying the system and reducing heat consumption. High water spraying density, can reach 180m3/m2•h. Therefore, the volume is small, and compared with deaerators of other models with the same output, a large amount of steel can be saved, thereby reducing equipment material costs.

Selection and Ordering Instructions

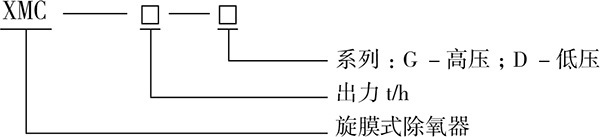

(1) Model Description

(2) Scope of Supply

Water tank body (including internal devices and saddles), deaerator tower body (including internal devices), on-site pressure gauge, on-site thermometer, glass tube level gauge, safety valve (or water seal)

Main Dimensions of XMC-G Type High-Pressure Rotary Film Deaerator

|

Model |

L1(mm) |

L2(mm) |

h1(mm) |

h2(mm) |

DN1(mm) |

DN2(mm) |

Water tank volume (m3) |

Effective water tank volume (m3) |

Deaerator tower volume (m3) |

|

XMC-1080G |

21000 |

6000 |

3934 |

4772 |

3400 |

3200 |

185 |

152 |

29.7 |

|

XMC-680G |

19000 |

6000 |

3880 |

3980 |

3400 |

2500 |

167 |

133 |

10.0 |

|

XMC-440G |

15000 |

4500 |

3700 |

3820 |

3200 |

2000 |

115 |

91 |

8.90 |

|

XMC-250G |

11000 |

3000 |

3500 |

3780 |

3000 |

1800 |

74 |

59 |

5.10 |

|

XMC-150G |

7000 |

2500 |

3200 |

3110 |

2800 |

1500 |

46 |

35 |

3.60 |

|

XMC-75G |

6000 |

1800 |

2624 |

2910 |

2200 |

1200 |

23 |

18 |

2.30 |

|

XMC-30G |

5000 |

1500 |

2450 |

2980 |

2000 |

1000 |

12 |

10 |

1.20 |

Technical Characteristics Table of XMC-G Type High-Pressure Rotary Film Deaerator

|

Model |

Operating Pressure (MPa) |

Inlet Water Temperature (°C) |

Outlet Temperature (°C) |

Inlet Dissolved Oxygen (μg/L) |

Outlet Dissolved Oxygen (μg/L) |

Operating Mode |

Makeup Water Rate (%) |

|

XMC-G |

-0.05~1.6 |

60~144 |

110~220 |

1600 |

Startup 30, Operation |

Sliding pressure, Constant pressure |

<100 |

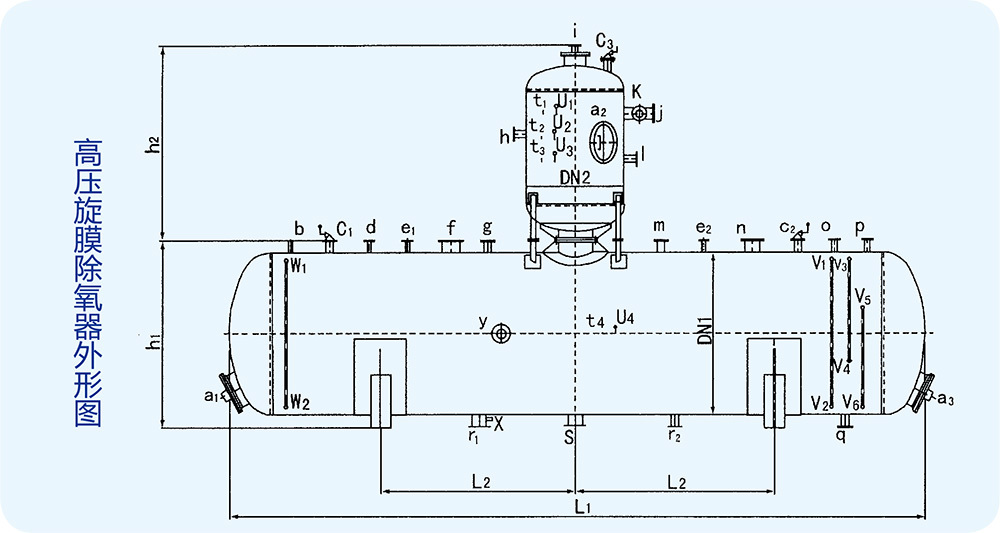

XMC-G Type High-Pressure Rotary Film Deaerator Port Table

|

Symbol |

Purpose or Name |

Symbol |

Purpose or Name |

Symbol |

Purpose or Name |

|

a1-3 |

Manhole |

j |

Feedwater Inlet |

s |

Drain Outlet |

|

b |

Reboiler Inlet |

k |

Makeup Water Inlet |

t1-4 |

Thermometer Connection |

|

c1-3 |

Safety Valve Outlet |

l |

High-Pressure Condensate Inlet |

μ1-4 |

Pressure Gauge Connection |

|

d |

Recirculation Outlet |

m |

Spare Outlet |

v1-6 |

Level Gauge Connection |

|

e1-2 |

Equilibrium Disk Leakage Inlet |

n |

Shaft Seal Steam Inlet |

w1-2 |

Liquid level signal port |

|

f |

Primary steam inlet |

o |

Exhaust pipe inlet |

x |

Sampling port |

|

g |

Gate stem leak inlet |

p |

Steam balance port |

y |

High-level electric drain port |

|

h |

Secondary steam inlet |

q |

Water balance port |

|

|

|

i |

Exhaust port |

r1-2 |

Outlet |

|

|

High-pressure rotary film deaerator outline drawing

Main dimensions of XMC-D type low-pressure rotary film deaerator

|

Model |

L1(mm) |

L2(mm) |

h1(mm) |

h2(mm) |

DN1(mm) |

DN2(mm) |

Water tank volume (m3) |

Effective water tank volume (m3) |

Deaerator tower volume (m3) |

|

XMC-350D |

14000 |

4000 |

3430 |

3560 |

3000 |

2000 |

95.2 |

76.0 |

10.1 |

|

XMC-250D |

11000 |

3000 |

3230 |

3360 |

2800 |

1800 |

67.2 |

58.0 |

6.46 |

|

XMC-150D |

9800 |

3000 |

2830 |

3160 |

2400 |

1500 |

45.0 |

36.0 |

4.40 |

|

XMC-75D |

6000 |

2000 |

3630 |

3010 |

2200 |

1200 |

21.3 |

17.0 |

2.60 |

|

XMC-40D |

5900 |

1500 |

2430 |

2980 |

2000 |

1000 |

17.7 |

15.0 |

2.00 |

|

XMC-25D |

5260 |

1300 |

2210 |

2742 |

1800 |

1000 |

12.6 |

10.0 |

1.60 |

|

XMC-10D |

4350 |

1150 |

1870 |

1132 |

1500 |

800 |

7.2 |

5.10 |

1.20 |

Technical characteristics table of XMC-D type low-pressure rotary film deaerator

|

Model |

Operating Pressure (MPa) |

Inlet Water Temperature (°C) |

Outlet Temperature (°C) |

Inlet Dissolved Oxygen (μg/L) |

Outlet Dissolved Oxygen (μg/L) |

Operating Mode |

Makeup Water Rate (%) |

|

XMC-D |

0.02~0.49 |

45 |

104~157 |

7600 |

Startup 100, operation 10 |

Sliding pressure, Constant pressure |

<100 |

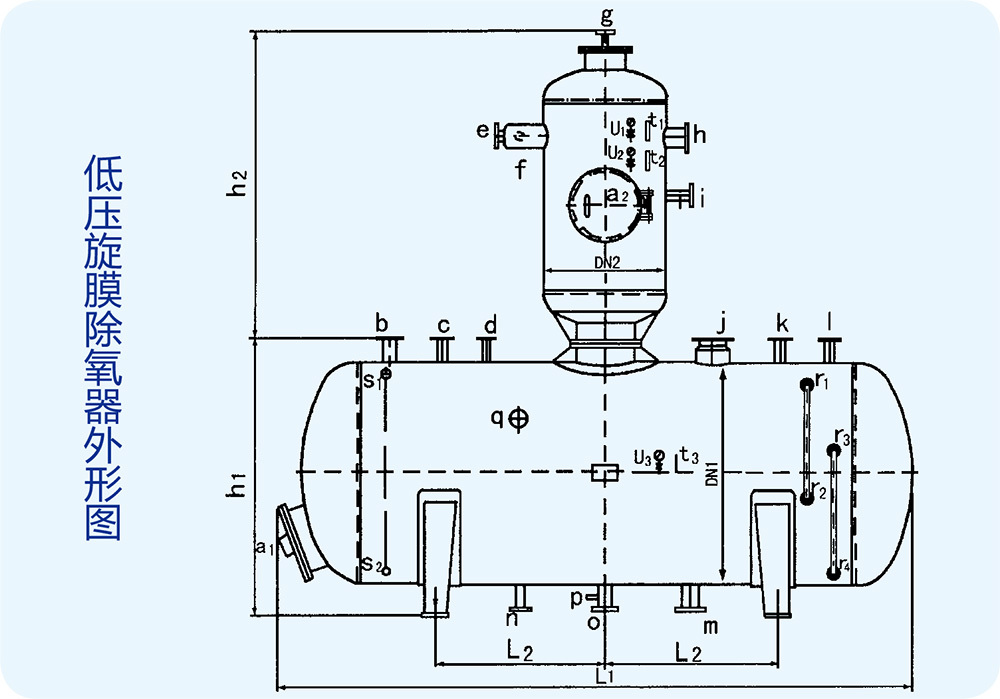

XMC-D type low-pressure rotary film deaerator port table

|

Symbol |

Purpose or Name |

Symbol |

Purpose or Name |

Symbol |

Purpose or Name |

|

a1-2 |

Manhole |

h |

Inspection port |

o |

Outlet |

|

b |

Spare Outlet |

i |

High-level drain port |

p |

Sampling port |

|

c |

Reboiler Inlet |

j |

Steam inlet |

q |

High-level drain port |

|

d |

Recirculation Outlet |

k |

Gate stem leak |

r1-4 |

Level Gauge Connection |

|

e |

Feedwater Inlet |

l |

Steam balance port |

s1-2 |

Liquid level signal port |

|

f |

Makeup Water Inlet |

m |

Water balance port |

t1-3 |

Thermometer Connection |

|

g |

Exhaust port |

n |

Drain Outlet |

u1-3 |

Pressure Gauge Connection |

Low-pressure rotary film deaerator outline drawing