Hydrocyclone Desander

Classification:

Hydrocyclone Desander

Details

Function Overview

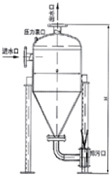

The vortex desander utilizes the principle of centrifugal separation for desanding. Because the inlet pipe is installed in an eccentric position on the cylinder, when water passes through the inlet pipe of the vortex desander, it first forms a downward oblique peripheral flow along the periphery of the cylinder. The water flows downward in a rotating manner. When the water flow reaches the conical part, it turns and rotates upward along the axis of the cylinder, and finally is discharged through the top outlet pipe. Impurities fall into the conical hopper at the bottom of the equipment under the action of fluid inertial centrifugal force and their own gravity along the conical wall. A component is installed at the bottom of the cone to prevent impurities from rising upwards. When the accumulated impurities in the hopper reach a certain level, the impurities can be discharged from the vortex desander under the action of water flow by simply opening the manual butterfly valve.

The vortex desander utilizes the principle of centrifugal separation for desanding. Because the inlet pipe is installed in an eccentric position on the cylinder, when water passes through the inlet pipe of the vortex desander, it first forms a downward oblique peripheral flow along the periphery of the cylinder. The water flows downward in a rotating manner. When the water flow reaches the conical part, it turns and rotates upward along the axis of the cylinder, and finally is discharged through the top outlet pipe. Impurities fall into the conical hopper at the bottom of the equipment under the action of fluid inertial centrifugal force and their own gravity along the conical wall. A component is installed at the bottom of the cone to prevent impurities from rising upwards. When the accumulated impurities in the hopper reach a certain level, the impurities can be discharged from the vortex desander under the action of water flow by simply opening the manual butterfly valve.

The vortex desander is a highly efficient desander with extremely convenient and reliable desanding. For rust, sand, and other impurities with an average volume of 1.8g/cm3 The separation particle size is 0.07mm; when the particle size is 0.3mm, the desanding efficiency can reach 97%, with absolutely no possibility of blockage and no need for special venting. It is currently the only non-blocking desander, which has incomparable advantages over filter-type desanders in protecting the safe operation of the water system.

The vortex desander can discharge wastewater during operation, that is, it is not necessary to shut down the water pump. Regularly discharge sand and wastewater according to the amount of sand contained in the source water. When discharging wastewater, open the wastewater valve until clear water flows out. The wastewater discharge process does not affect the normal water use of the system.

Safe Operation Tips:The discharge pipe should be as long as possible, and the discharge valve should be installed as far away as possible to increase the storage capacity of sand, reduce the scouring of sand on the shell, and effectively increase the service life of the equipment.

Model and Technical Parameters

|

Specifications |

Water Treatment Capacity (m³\/h)3/h |

Inlet/Outlet DN (mm) |

Discharge Port DN (mm) |

ФDN (mm) |

Hmm (mm) |

|

CSQ-40 |

3~6 |

40 |

40 |

300 |

1100 |

|

CSQ-50 |

6~10 |

50 |

40 |

300 |

1100 |

|

CSQ-65 |

10~16 |

65 |

40 |

350 |

1200 |

|

CSQ-80 |

16~25 |

80 |

40 |

400 |

1300 |

|

CSQ-100 |

25~55 |

100 |

40 |

400 |

1300 |

|

CSQ-125 |

55~85 |

125 |

50 |

500 |

1500 |

|

CSQ-150 |

85~120 |

150 |

50 |

600 |

1500 |

|

CSQ-200 |

120~240 |

200 |

50 |

700 |

1800 |

|

CSQ-250 |

240~350 |

250 |

50 |

800 |

2000 |

|

CSQ-300 |

350~500 |

300 |

50 |

1000 |

2200 |

|

CSQ-350 |

500~600 |

350 |

50 |

1200 |

2500 |

WeChat Mini Program

WeChat public account

Service line:

Mobile:+86-15064136769

+86-13869137166

Mailbox:zhilin@sdzhilin.cn

Address: South Park, Jinan Economic Development Zone, Shandong Province