CY series ambient temperature sponge iron deaerator

Classification:

CY series ambient temperature sponge iron deaerator

Details

Product Overview

The CY series ambient temperature sponge iron deoxygenator uses high-activity sponge iron deoxygenating agent to remove dissolved oxygen from water. The treated water can be widely used in boiler feed water and industrial circulating water equipment for corrosion prevention, and is an ideal environmentally friendly deoxygenation equipment.

Deoxygenation Mechanism

The high-activity filler-type sponge iron deoxygenating agent obtained after activation treatment is a sponge-like porous iron particle, which is best for softening water deoxygenation and has a filtering effect. The activated iron rapidly undergoes an oxidation-reduction reaction with dissolved oxygen in the water, and the reaction formula is:

Fe+H2O+1/2O2 → Fe2++2OH-

Fe2++2OH+1/4O2+2H2O-Fe(OH)3 ↓

The ferric hydroxide flocs generated by the reaction accumulate on the surface of the high-activity sponge iron deoxygenating agent and are intercepted, and are easily washed away and discharged by backwashing water, and the deoxygenating agent quickly recovers its initial activity.

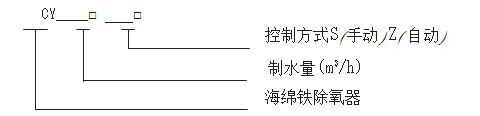

Model Representation

Technical Parameter Table

|

Model |

CY-4 |

CY-6 |

CY-10 |

CY-15 |

CY-20 |

CY-25 |

CY-30 |

CY-35 |

CY-40 |

CY-50 |

|

|

Water Production (m³/h)3/h) |

4 |

6 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

50 |

|

|

Dimensions |

Tank Diameter (mm) |

600 |

800 |

1000 |

1100 |

1200 |

1400 |

1500 |

1700 |

1800 |

2000 |

|

Tank Height (mm) |

2600 |

2600 |

2800 |

2800 |

3000 |

3000 |

2200 |

2200 |

2400 |

2400 |

|

|

Ground Area (mm) |

800 |

1000 |

1200 |

1300 |

1400 |

1600 |

1700 |

1900 |

2100 |

2300 |

|

|

External Pipe Diameter |

Inlet (mm) |

32 |

40 |

50 |

65 |

65 |

80 |

80 |

100 |

100 |

125 |

|

Outlet (mm) |

40 |

50 |

65 |

65 |

80 |

100 |

100 |

125 |

125 |

150 |

|

|

Backwash Port (mm) |

40 |

50 |

65 |

65 |

80 |

100 |

100 |

125 |

125 |

150 |

|

|

Equipment Weight (kg) |

1300 |

1800 |

3400 |

4200 |

5000 |

6600 |

7500 |

9900 |

10000 |

13400 |

|

|

Sponge Iron Weight (kg) |

550 |

830 |

1400 |

2100 |

2800 |

3500 |

4200 |

4880 |

5580 |

6350 |

|

|

Filler Layer Height (mm) |

1200 |

1200 |

1200 |

1200 |

1200 |

1200 |

1200 |

1200 |

1200 |

1200 |

|

|

Working Pressure |

0.15~0.5MPa |

||||||||||

|

Backwash Intensity |

16~21L/m2·s |

||||||||||

|

Operating Temperature |

0~200℃ |

||||||||||

|

Control Method |

Z is automatic control (backwashing according to pressure difference or oxygen content) S is manual control (backwashing according to pressure difference or timing) |

||||||||||

|

Note: Single-tank or double-tank types can be designed according to customer needs. |

|||||||||||

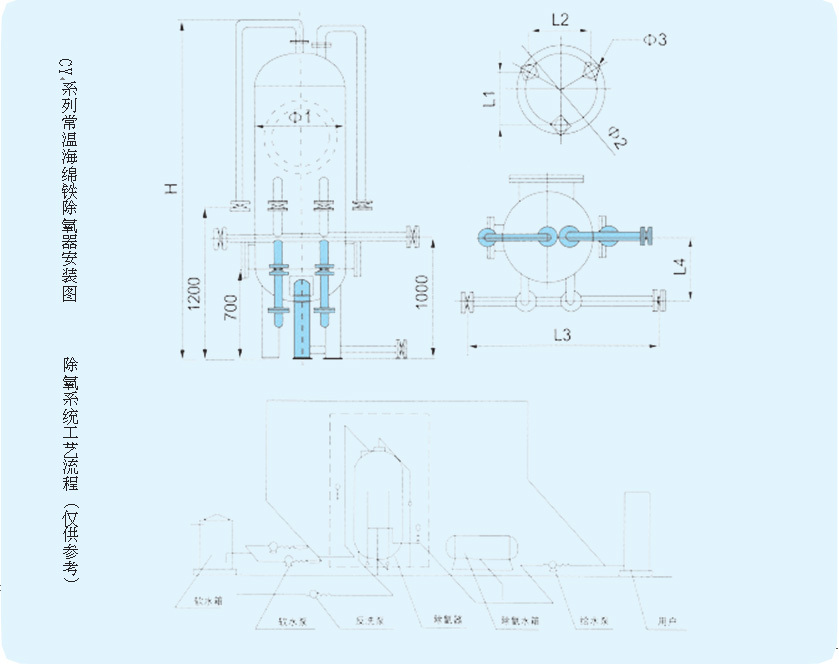

Installation Dimensions (unit: mm)

|

Model |

H |

L1 |

L2 |

L3 |

L4 |

Φ1 |

Φ2 |

Φ3 |

|

CY-4S |

2580 |

360 |

416 |

1000 |

560 |

600 |

480 |

24 |

|

CY-6S |

2580 |

420 |

485 |

1350 |

610 |

800 |

560 |

24 |

|

CY-10S |

3200 |

563 |

650 |

1500 |

750 |

1000 |

750 |

24 |

|

CY-15S |

3200 |

600 |

693 |

1650 |

850 |

1100 |

800 |

24 |

|

CY-20S |

3450 |

630 |

728 |

1750 |

900 |

1200 |

840 |

24 |

|

CY-25S |

3450 |

788 |

909 |

1950 |

1050 |

1400 |

1050 |

24 |

|

CY-30S |

3550 |

825 |

953 |

2050 |

1100 |

1500 |

1100 |

24 |

|

CY-35S |

3550 |

975 |

1126 |

2250 |

1250 |

1700 |

1300 |

24 |

|

CY-40S |

3850 |

1050 |

1212 |

2350 |

1350 |

1800 |

1400 |

24 |

|

CY-50S |

3850 |

1200 |

1386 |

3550 |

1500 |

2000 |

1600 |

30 |

Note:1. The deoxygenating agent is used in the deoxygenator within the dashed line in 2.

2. Our company can assist users in designing the deoxygenating agent usage process.

Precautions:

1. The handling and storage of the deoxygenating agent should keep the packaging intact, protect from rain and moisture.

2. Generally, the deoxygenating agent filler height is about 1.2 meters, and it should be increased or decreased appropriately according to different water quality in different places.