Enhanced turbulent heat exchanger - heat exchanger - heat exchanger manufacturer

Shandong Zhilin Environmental Protection Technology Co., Ltd. is a professional heat exchanger manufacturer in China, integrating the research, production, and sales of plate heat exchangers, detachable heat exchangers, high-efficiency plate heat exchangers, steam-water high-efficiency plate heat exchangers, enhanced turbulent flow heat exchangers, high-efficiency intelligent heat exchanger units, plate heat exchanger units, and intelligent heat exchanger units. The enhanced turbulent flow heat exchanger is a high-efficiency and energy-saving shell and tube heat exchange equipment. It uses stainless steel or copper tubes with special double-threaded heat exchange tubes, featuring high heat transfer coefficient, strong automatic descaling ability, and safe and reliable operation. It has good comprehensive economic performance and is a substitute for traditional shell and tube heat exchangers.

Classification:

Enhanced turbulent heat exchanger

Details

Overview

The enhanced turbulent heat exchanger is a highly efficient and energy-saving shell and tube heat exchange equipment. Using specially made double-threaded heat exchange tubes of stainless steel or copper, it features high heat transfer coefficient, strong self-cleaning ability, and reliable operation. It boasts excellent comprehensive economic performance and serves as a replacement for traditional shell and tube heat exchangers.

Enhanced turbulent heat exchangers are divided into steam-water heat exchange and water-water heat exchange according to different heat mediums, and into vertical and horizontal types according to installation methods. Convenient to choose, with complete models, they can also be specially designed according to specific situations. It is a new type of enhanced heat transfer and high-efficiency energy-saving heat exchange equipment, widely used in production, heating, air conditioning and other heat exchange occasions, and is widely praised by users.

Main Features of Enhanced Turbulent Heat Exchanger

■ Good Antifouling Performance:On the one hand, the double-threaded heat exchange tube makes the fluid turbulence sufficient, destroying the conditions for fouling generation and reducing fouling. On the other hand, the double-threaded tube can have slight elastic deformation under temperature difference impact, thus breaking down the already formed fouling.

■ High Heat Transfer Coefficient:The special shape of the double-threaded heat exchange tube ensures that both internal and external flowing media are in a turbulent state, thus destroying the boundary layer of the media and improving the heat transfer coefficient inside and outside the tube. Under normal conditions, the overall heat transfer coefficient can also be greatly improved.

■ Strong Corrosion Resistance:Due to the high heat transfer coefficient, less material is used, and the double-threaded tube has high strength and thin material, resulting in much less material used for the heat exchange tube compared to ordinary tubes. In this way, the heat exchange tube can be made of materials with good corrosion resistance, such as stainless steel and copper, without increasing the cost, thus improving the corrosion resistance of the components.

■ Energy Saving, Water Saving, and Electricity Saving:It has significant energy saving and material saving effects in closed-loop systems.

■ Simple Structure:Because the double-threaded tube has moderate elasticity and its own thermal expansion and contraction compensation capacity, the thermal stress of the heat exchanger is correspondingly reduced during the heat transfer process, and the expansion joints are not easy to leak. Therefore, compensators can be omitted, simplifying the structure.

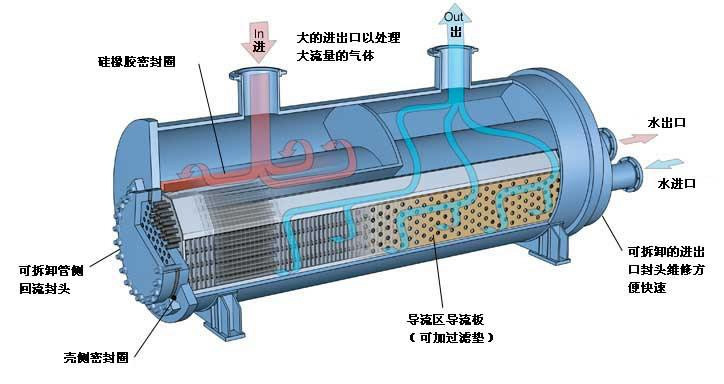

Enhanced Turbulent Heat Exchanger Structure Diagram

Equipment Specifications, Dimensions, and Parameter Table

|

Model |

Equipment Appearance |

Heat Transfer Capacity KW at 0.6MPa Steam |

Heat Transfer Capacity KW at 95/70 |

||

|

85/60 |

60/50 |

60/50 |

60/50 |

||

|

SHQN125-1.0- △ |

DN125*2120 |

140 |

150 |

18 |

36 |

|

SHQN150-1.5- △ |

DN150*2120 |

210 |

225 |

27 |

55 |

|

SHQN200-3.0- △ |

DN200*2150 |

420 |

450 |

54 |

110 |

|

SHQN250-4.0- △ |

DN250*2300 |

560 |

600 |

72 |

150 |

|

SHQN250-5.0- △ |

DN250*2300 |

700 |

750 |

90 |

180 |

|

SHQN300-6.0- △ |

DN300*2300 |

840 |

900 |

108 |

220 |

|

SHQN300-8.0- △ |

DN300*2300 |

1120 |

1200 |

144 |

288 |

|

SHQN350-10- △ |

DN350*2350 |

1400 |

1500 |

180 |

360 |

|

SHQN400-15- △ |

DN400*2450 |

2100 |

2250 |

270 |

540 |

|

SHQN400-20- △ |

DN400*2950 |

2800 |

3000 |

360 |

720 |

|

SHQN500-23- △ |

DN500*2450 |

3200 |

3450 |

414 |

828 |

|

SHQN500-30- △ |

DN500*2950 |

4200 |

4500 |

540 |

1080 |

|

SHQN600-40- △ |

DN600*2600 |

5600 |

6000 |

720 |

1400 |

|

SHQN600-50- △ |

DN600*3100 |

7000 |

8000 |

900 |

1800 |

|

SHQN700-55- △ |

DN700*2900 |

7700 |

8800 |

990 |

1980 |

|

SHQN700-70- △ |

DN700*3400 |

9800 |

10800 |

1260 |

2520 |

|

SHQN800-80- △ |

DN800*3450 |

11200 |

12000 |

1400 |

2800 |

|

SHQN800-100- △ |

DN800*3950 |

14000 |

16000 |

1800 |

3600 |

|

SHQN900-110- △ |

DN900*3650 |

15400 |

17600 |

1980 |

3960 |

|

SHQN1000-140- △ |

DN1000*4800 |

19600 |

21600 |

2520 |

5000 |

|

SHQN1000-170- △ |

DN1000*4800 |

23800 |

26100 |

3060 |

6100 |