Plate heat exchanger

Disassembleable plate heat exchangers are currently the most popular home heat exchangers, especially in winter. In cold climates, if the house doesn't have heating, using this type of disassembleable plate heat exchanger is very practical. A good disassembleable plate heat exchanger can bring endless heat to the room, providing warmth for people and for drying clothes, etc.

Classification:

Plate heat exchanger

Details

Basic Introduction

The dismountable plate heat exchanger is currently the most popular household heat exchanger, especially in winter. In cold climates, if the house does not have heating, using this type of dismountable plate heat exchanger is very practical. A good dismountable plate heat exchanger can bring endless heat to the room, providing warmth for people and drying clothes, etc.

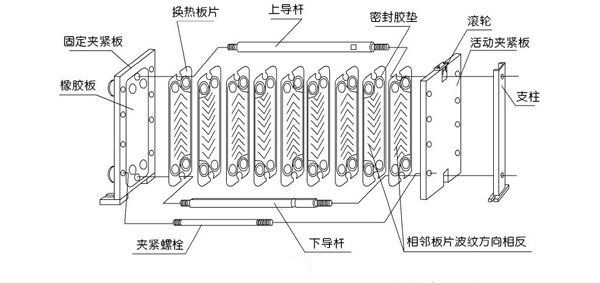

Plate heat exchangers are dismountable heat exchange devices composed of many corrugated heat transfer plates, arranged at a certain interval, and pressed together by rubber gaskets. When the plates are assembled, two sets are arranged alternately. The plates are fixed together with rubber seals, which prevent liquid leakage and form narrow mesh-shaped flow channels between the two plates. The heat exchange plates are pressed into various corrugated shapes to increase the heat exchange area and rigidity, and to allow the liquid to form turbulence at low flow rates to achieve enhanced heat transfer. The four corner holes on the plate form the liquid distribution pipe and collecting pipe. The two heat exchange media flow into their respective channels and form countercurrent flow through each plate to exchange heat.

Technical Characteristics

Excellent Flow Guiding Design

The inlet distribution area of the plates is designed with streamlined guide grooves, which have the effect of reducing the difference in flow resistance on different flow channels, so that the fluid is evenly distributed in the plate heat exchange area, thus avoiding the decrease in heat exchange efficiency, pitting, and scaling caused by uneven flow distribution and stagnant flow areas. For plates with a larger width, equipotential pressure grooves are also added, so that the resistance formed by the intersection of the streamline guide groove and the equipotential pressure groove is very small, and a grid-like inlet distribution area with a near-perfect flow averaging effect is formed. At the same time, the distribution area also plays the role of quickly forming turbulent and strong heat exchange, making the distribution area participate in heat exchange in advance, effectively increasing the heat exchange length and reducing the heat exchange area.

Advanced Positioning Structure

The plates use a dovetail groove-shaped hanging positioning system. This system has three functions:

Hanging: The plates are hung on the guide rod, allowing them to slide freely along the upper guide rod;

Positioning: The plates are accurately positioned up, down, left, and right;

Locking: The newly designed dovetail groove folding edge allows the plates to automatically lock each other during clamping, ensuring that all plates are accurately aligned under any installation conditions, avoiding deviations caused by human factors. Using the concave-convex groove positioning technology of the four corners of the plates ensures that the plates interlock and will never misalign during assembly.

Plate Material of Plate Heat Exchanger

|

Material |

|

Applicable Medium |

|

Stainless Steel |

SUS304/SUS304L/SUS316/SUS316L/SUS321/ SUS310S/SUS317L /SMO254 |

Water, steam, edible oil, mineral oil, acid-base media, not suitable for occasions with high chloride ion content |

|

Titanium plate, nickel plate |

TA1 TA2 |

Brine, seawater, and occasions with high chloride ion content |

|

Hastelloy |

Hastelloy C-276 |

Occasions with concentrated sulfuric acid, hydrochloric acid, phosphoric acid, and strong oxidizing media |

|

Aluminum plate |

|

Substitute for SUS316L in brine and seawater applications |

Gasket Material of Plate Heat Exchanger

|

Material |

Operating Temperature |

Applicable Medium |

|

EPDM |

-20~150℃ |

Water, steam, general organic and inorganic acids, alkalis, and chemical media |

|

NBR |

-20~120℃ |

Water, oils, aldehydes, and general corrosive media |

|

FKM |

0~180℃ |

Organic solutions, acids, alkalis, alcohols, oils, water, steam |

|

Silicone Rubber |

-20~230℃ |

High-temperature applications, some oils, alcohol |

|

Neoprene |

-20~150℃ |

Water, Freon |

|

Food grade rubber |

-20~150℃ |

Various food materials, pharmaceutical materials |

Plate Type Size Table of Dismountable Plate Heat Exchanger

|

BR equal cross-section series (BRB unequal cross-section series) |

||||

|

Pipe Size |

Model |

Equipment Dimensions |

BR Pipe Center Distance |

BRB Pipe Center Distance |

|

DN40 or DN50 |

BR0.12 |

580*320 |

340*146 |

|

|

BR0.18 |

830*320 |

590*146 |

|

|

|

DN65-DN80 (DN65/DN80) |

BR0.21 |

836*420 |

464*200 |

464*200 |

|

BR0.28 |

916*420 |

664*200 |

664*200 |

|

|

BR0.31 |

1016*420 |

764*200 |

764*200 |

|

|

BR0.38 |

1216*420 |

965*200 |

964*200 |

|

|

DN100 (DN100/DN125) |

BR0.36 |

1091*490 |

703*240 |

703*240 |

|

BR0.41 |

1219*490 |

830*240 |

830*240 |

|

|

BR0.50 |

1438*490 |

1050*240 |

1050*240 |

|

|

DN125-DN150 (DN125/DN150) |

BR0.46 |

1200*610 |

682*286 |

705*675*289 |

|

BR0.61 |

1500*610 |

982*286 |

1005*975*289 |

|

|

BR0.76 |

1800*610 |

1280*286 |

1305*1275*289 |

|

|

DN200 (DN150/DN200) |

BR0.65 |

1370*726 |

788*344 |

839*789*369 |

|

BR0.81 |

1630*726 |

1095*344 |

1101*1051*369 |

|

|

BR0.87 |

1726*726 |

1150*344 |

1195*1145*369 |

|

|

BR1.08 |

2064*726 |

1484*344 |

1532*1482*369 |

|

|

DN250(DN200/DN250) |

BR1.05 |

1719*837 |

1080*434 |

1130*1080*459 |

|

BR1.35 |

2189*837 |

1480*434 |

1530*1480*459 |

|

|

BR1.6 |

2489*837 |

1780*434 |

1830*1780*459 |

|

|

DN300-DN350 |

BR1.7 |

2155*1118 |

1289*585 |

|

|

BR2.0 |

2455*1118 |

1589*585 |

|

|

|

BR2.3 |

2755*1118 |

1889*585 |

|

|

|

DN400/DN450/500 |

BR2.7 |

2665*1358 |

1642*676 |

|

|

BR3.15 |

3045*1358 |

2004*676 |

|

|

|

BR3.6 |

3425*1358 |

2384*676 |

|

|

Plate type heat exchanger plate size table (shallow corrugated)

|

BR equal cross-section series (BRB unequal cross-section series) |

||||

|

Pipe Size |

Model |

Equipment Dimensions |

BR Pipe Center Distance |

BRB Pipe Center Distance |

|

DN100 |

M041 |

1219*490 |

831*240 |

|

|

M05 |

1438*490 |

1050*240 |

|

|

|

DN150 |

M075 |

2070*726 |

1482*344 |

|

|

M09 |

2214*726 |

1632*344 |

|

|

|

DN200 |

M11 |

1800*610 |

1282*286 |

|

|

M12 |

2100*610 |

1582*286 |

|

|