Finned tube heat exchanger

Shandong Zhilin Environmental Protection Technology Co., Ltd. is a professional manufacturer of heating units and heat exchangers. The company's main products include heating units such as intelligent heat exchange units, plate heat exchange units, and high-efficiency intelligent heat exchange units; heat exchanger products include detachable heat exchangers, finned tube heat exchangers, water-water plate heat exchangers, high-efficiency plate heat exchangers, gasket plate heat exchangers, detachable plate heat exchangers, steam-water high-efficiency plate heat exchangers, high-temperature plate heat exchangers, heat exchangers, and plate heat exchangers.

Classification:

Finned tube heat exchanger

Details

Shandong Zhilin Environmental Protection Technology Co., Ltd. is a professional manufacturer of heating units and heat exchangers. The company's main products include heating units such as intelligent heat exchange units, plate heat exchange units, and high-efficiency intelligent heat exchange units; heat exchanger products include detachable heat exchangers, finned tube heat exchangers, water-water plate heat exchangers, high-efficiency plate heat exchangers, gasket plate heat exchangers, detachable plate heat exchangers, steam-water high-efficiency plate heat exchangers, high-temperature plate heat exchangers, heat exchangers, and plate heat exchangers, etc.

Principle and selection of finned tube heat exchanger

Currently, the most widely used finned tube heat exchanger is the steel-aluminum finned tube (coiled steel-aluminum composite finned tube, rolled steel-aluminum composite finned tube). It utilizes the pressure resistance of steel pipes and the high thermal conductivity of aluminum, and is compounded on a special machine tool. Its contact thermal resistance is almost zero under working conditions of 210'C.

Finned tube heat exchangers are generally used for heating or cooling air, and have the characteristics of compact structure and large unit heat transfer area. They are widely used in various fields such as domestic waste treatment, textile, printing and dyeing, petroleum, chemical industry, drying, and power generation.

The heating medium (steam or hot water) of the heating system is mainly transferred to the room through the wall of the heat dissipation equipment by convection heat transfer (convection heat transfer is greater than radiation heat transfer). This type of heat dissipation equipment is commonly known as a finned tube heat exchanger. Finned tube heat exchangers made of steel finned tubes are commonly called finned tube heat exchangers. This is both its definition and its principle. So how should it be selected?

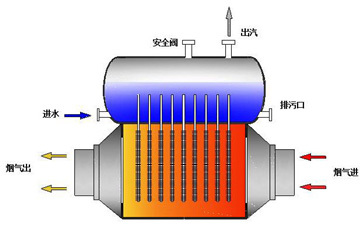

Finned tube heat exchanger structure diagram

In fact, as long as you know its basic requirements, you won't be confused when selecting. The basic requirements are as follows:

1. Requirements for thermal performance. The higher the heat transfer coefficient K value of the finned tube heat exchanger, the better its heat dissipation performance. To improve the heat dissipation of the radiator and increase the heat transfer coefficient of the finned tube heat exchanger, methods such as increasing the external wall heat dissipation area (finned radiator), increasing the air flow speed around the radiator, and increasing the outward radiation intensity of the radiator can be adopted.

2. Economic requirements. The less metal consumption per unit of heat transferred to the room by the finned tube heat exchanger, the lower the cost and the better the economic performance. The metal thermal strength of the finned tube heat exchanger is an indicator to measure the economic performance of the radiator. Metal thermal strength refers to the amount of heat dissipated per unit time per kilogram of radiator mass when the temperature difference between the average temperature of the heating medium inside the radiator and the indoor air temperature is 1"C. This indicator can be used as an indicator to measure the economic performance of radiators of the same material. For finned tube heat exchangers of different materials, the economic evaluation standard should be measured by the cost (yuan/w) per unit heat dissipation of the finned tube heat exchanger.

3. Requirements for installation, use and process. The finned tube heat exchanger should have a certain mechanical strength and pressure bearing capacity; the structural form of the finned tube heat exchanger should be easy to combine into the required heat dissipation area, the structural size should be small, occupying less room area and space, and the production process of the finned tube heat exchanger should meet the requirements of mass production.

4. Requirements for hygiene and aesthetics. The surface of the finned tube heat exchanger is smooth, does not accumulate dust and is easy to clean, and the installation of the finned tube heat exchanger should not affect the appearance of the room.

5. Requirements for service life. The finned tube heat exchanger should not be easily corroded or damaged, and have a long service life.