High-temperature plate heat exchanger

Shandong Zhilin Environmental Protection Technology Co., Ltd. is a professional heat exchanger manufacturer specializing in the research, development, production, and sales of plate heat exchangers, detachable heat exchangers, high-efficiency plate heat exchangers, high-efficiency steam-water plate heat exchangers, high-efficiency intelligent heat exchanger units, plate heat exchanger units, and intelligent heat exchanger units. High-temperature plate heat exchangers are mainly used in various industries' waste heat recovery from flue gas and heat exchange required in various process systems in the energy-saving and emission-reduction industry. Through heat exchange, the waste heat flue gas is cooled, and the waste heat recovery system achieves energy saving, thereby improving corporate economic benefits, reducing operating costs, and enhancing competitiveness. It has been successfully used in various VOC treatment equipment. High-efficiency intelligent heat exchanger units are widely used in the chemical, chemical fertilizer, pharmaceutical, petroleum, and steel industries.

Classification:

Product Center

Details

Shandong Zhilin Environmental Protection Technology Co., Ltd. is a professional heat exchanger manufacturer in China focusing on the research, development, production, and sales of plate heat exchangers, dismountable heat exchangers, high-efficiency plate heat exchangers, high-efficiency steam-water plate heat exchangers, high-efficiency intelligent heat exchanger units, plate heat exchanger units, and intelligent heat exchanger units.,Production,Sales

Zhilin Environmental Protection Technology, as a heat exchanger manufacturer, mainly produces plate heat exchangers, intelligent heat exchanger units, dismountable heat exchangers, water-water plate heat exchangers, high-efficiency plate heat exchangers, gasket plate heat exchangers, dismountable plate heat exchangers, and high-efficiency intelligent heat exchanger units. These products are widely used in chemical, chemical fertilizer, pharmaceutical, petroleum, steel, liquor, food, beverage, printing and dyeing, power, coating, rubber, heating, and hotel industries, and can also meet the requirements of heating, cooling, condensation, heat recovery, and various processes. Supported by strong technical strength, Zhilin Environmental Protection Technology, with advanced production and testing equipment, perfect and scientific enterprise management, and a harmonious and united production and sales team, strives to provide customers with high-performance, reliable, and cost-effective products.

Basic Introduction

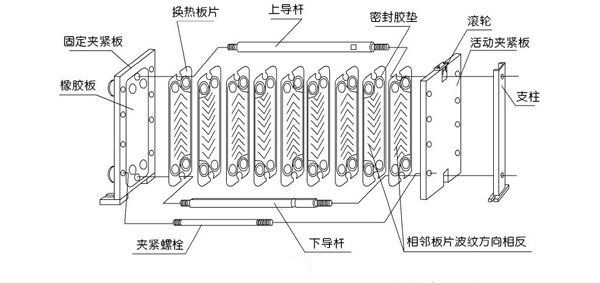

A plate heat exchanger is a dismountable heat exchange equipment composed of many corrugated heat transfer plates, arranged at a certain interval and pressed together by rubber gaskets. When the plates are assembled, two sets are arranged alternately, and the plates are fixed together with rubber sealing strips to prevent liquid leakage and form a narrow mesh-like flow channel between the two plates. The heat exchange plates are pressed into various corrugated shapes to increase the heat exchange area and rigidity, and to enable the liquid to form turbulence at low flow rates to enhance the heat transfer effect. The four corner holes on the plate form the liquid distribution and collection pipes, and the two heat exchange media flow into their respective channels, forming a countercurrent flow through each plate to exchange heat.

Technical Features

Excellent Flow Guiding Design

The inlet distribution area of the plates is designed with streamlined guide grooves, which have the function of reducing the difference in flow resistance on different flow channels, so that the fluid is evenly distributed in the plate heat exchange area, thus avoiding the reduction of heat exchange efficiency, pitting, and scaling caused by uneven flow distribution and flow dead zones. For plates with larger widths, additional equipotential pressure grooves are added, so that the resistance formed by the intersection of the streamline guide grooves and the equipotential pressure grooves is very small, resulting in a grid-like inlet distribution area with a near-perfect flow distribution effect. At the same time, the distribution area also plays a role in rapidly forming turbulent and strong heat exchange, making the distribution area participate in heat exchange in advance, effectively increasing the heat exchange length and reducing the heat exchange area.

Advanced Positioning Structure

The plates adopt a dovetail groove suspension positioning system. This system has three functions:

Suspension: Suspend the plates on the guide rods, allowing them to slide freely along the upper guide rods;

Positioning: Ensure accurate positioning of the plates up, down, left, and right;

Locking: The newly designed dovetail groove folding edge allows the plates to automatically lock each other when clamped, ensuring that all plates are precisely aligned under any installation conditions, avoiding deviations caused by human factors. The four-corner concave-convex groove positioning technology is used to make the plates interlock and lock during assembly, ensuring that they never misalign.

Plate Heat Exchanger Plate Material

|

Material |

|

Applicable Medium |

|

Stainless Steel |

SUS304/SUS304L/SUS316/SUS316L/SUS321/ SUS310S/SUS317L /SMO254 |

Water, steam, edible oil, mineral oil, acid-base media, not suitable for occasions with high chloride ion content |

|

Titanium Plate, Nickel Plate |

TA1 TA2 |

Brine, seawater, and occasions with high chloride ion content |

|

Hastelloy |

Hastelloy C-276 |

Concentrated sulfuric acid, hydrochloric acid, phosphoric acid, and strong oxidizing media |

|

Aluminum Plate |

|

Substitute for SUS316L in brine and seawater applications |

Plate Heat Exchanger Gasket Material

|

Material |

Operating Temperature |

Applicable Medium |

|

EPDM |

-20~150℃ |

Water, steam, general organic and inorganic acids, alkalis, and chemical media |

|

NBR |

-20~120℃ |

Water, oils, aldehydes, and general corrosive media |

|

FKM |

0~180℃ |

Organic solutions, acids, alkalis, alcohols, oils, water, steam |

|

Silicone Rubber |

-20~230℃ |

High-temperature applications, some oils, alcohol |

|

Neoprene |

-20~150℃ |

Water, Freon |

|

Food Grade Rubber |

-20~150℃ |

Various food materials, pharmaceutical materials |

Dismountable Plate Heat Exchanger Plate Size Table

|

BR Equal Section Series (BRB Unequal Section Series) |

||||

|

Inlet Size |

Model Number |

Equipment Dimensions |

BR Inlet Center Distance |

BRB Inlet Center Distance |

|

DN40 or DN50 |

BR0.12 |

580*320 |

340*146 |

|

|

BR0.18 |

830*320 |

590*146 |

|

|

|

DN65-DN80 (DN65/DN80) |

BR0.21 |

836*420 |

464*200 |

464*200 |

|

BR0.28 |

916*420 |

664*200 |

664*200 |

|

|

BR0.31 |

1016*420 |

764*200 |

764*200 |

|

|

BR0.38 |

1216*420 |

965*200 |

964*200 |

|

|

DN100 (DN100/DN125) |

BR0.36 |

1091*490 |

703*240 |

703*240 |

|

BR0.41 |

1219*490 |

830*240 |

830*240 |

|

|

BR0.50 |

1438*490 |

1050*240 |

1050*240 |

|

|

DN125-DN150 (DN125/DN150) |

BR0.46 |

1200*610 |

682*286 |

705*675*289 |

|

BR0.61 |

1500*610 |

982*286 |

1005*975*289 |

|

|

BR0.76 |

1800*610 |

1280*286 |

1305*1275*289 |

|

|

DN200 (DN150/DN200) |

BR0.65 |

1370*726 |

788*344 |

839*789*369 |

|

BR0.81 |

1630*726 |

1095*344 |

1101*1051*369 |

|

|

BR0.87 |

1726*726 |

1150*344 |

1195*1145*369 |

|

|

BR1.08 |

2064*726 |

1484*344 |

1532*1482*369 |

|

|

DN250(DN200/DN250) |

BR1.05 |

1719*837 |

1080*434 |

1130*1080*459 |

|

BR1.35 |

2189*837 |

1480*434 |

1530*1480*459 |

|

|

BR1.6 |

2489*837 |

1780*434 |

1830*1780*459 |

|

|

DN300-DN350 |

BR1.7 |

2155*1118 |

1289*585 |

|

|

BR2.0 |

2455*1118 |

1589*585 |

|

|

|

BR2.3 |

2755*1118 |

1889*585 |

|

|

|

DN400/DN450/500 |

BR2.7 |

2665*1358 |

1642*676 |

|

|

BR3.15 |

3045*1358 |

2004*676 |

|

|

|

BR3.6 |

3425*1358 |

2384*676 |

|

|

Plate Dimensions Table for Detachable Plate Heat Exchanger (Shallow Corrugated)

|

BR Equal Section Series (BRB Unequal Section Series) |

||||

|

Inlet Size |

Model Number |

Equipment Dimensions |

BR Inlet Center Distance |

BRB Inlet Center Distance |

|

DN100 |

M041 |

1219*490 |

831*240 |

|

|

M05 |

1438*490 |

1050*240 |

|

|

|

DN150 |

M075 |

2070*726 |

1482*344 |

|

|

M09 |

2214*726 |

1632*344 |

|

|

|

DN200 |

M11 |

1800*610 |

1282*286 |

|

|

M12 |

2100*610 |

1582*286 |

|

|

A heat exchanger is a device that transfers some of the heat from a hot fluid to a cold fluid. Also known as a thermal exchanger, it plays a significant role in various industries, including chemical, petroleum, power generation, and food processing. In chemical production, heat exchangers serve as heaters, coolers, condensers, evaporators, and reboilers, showcasing broad applications. Different heat exchangers are designed for various media, operating conditions, temperatures, and pressures, resulting in diverse structural designs.

A plate heat exchanger is a highly efficient heat exchanger composed of a series of metal plates with a certain corrugated shape stacked together. Thin rectangular channels are formed between the plates, allowing heat exchange through the plates. Plate heat exchangers are ideal equipment for liquid-liquid and liquid-vapor heat exchange. They are characterized by high heat exchange efficiency, low heat loss, compact and lightweight structure, small footprint, wide application, and long service life. Under the same pressure loss, its heat transfer coefficient is 3-5 times higher than that of a tube heat exchanger, its footprint is one-third that of a tube heat exchanger, and its heat recovery rate can be as high as 90% or more. The main types of plate heat exchangers are frame type (dismountable heat exchanger) and brazed type, and the main plate types are herringbone corrugated plate heat exchanger, horizontal straight corrugated plate heat exchanger, and embossed plate heat exchanger. According to the heat exchange medium, they can be divided into: water-water plate heat exchanger, steam-water high-efficiency plate heat exchanger, and high-temperature plate heat exchanger.

The plate heat exchanger unit automatically and continuously converts the heat obtained from the primary network into domestic water and heating water required by the user. That is, hot water enters the plate heat exchanger from the primary side inlet, undergoes heat exchange, and flows out from the primary side outlet; the secondary side return water, after having impurities removed by a filter, enters the plate heat exchanger through the secondary side circulating pump for heat exchange, producing hot water of different temperatures for heating, air conditioning, floor heating, or domestic water use to meet user needs.

A plate heat exchanger is a highly efficient heat exchanger composed of a series of metal plates with a certain corrugated shape stacked together. Thin rectangular channels are formed between the plates, allowing heat exchange through the plates. Plate heat exchangers are ideal equipment for liquid-liquid and liquid-vapor heat exchange. They are characterized by high heat exchange efficiency, low heat loss, compact and lightweight structure, small footprint, wide application, and long service life. Under the same pressure loss, its heat transfer coefficient is 3-5 times higher than that of a tube heat exchanger, its footprint is one-third that of a tube heat exchanger, and its heat recovery rate can be as high as 90% or more.

The main types of plate heat exchangers are frame type (removable) and brazed type, and the main plate types are herringbone corrugated plates, horizontal straight corrugated plates, and embossed plates.